The Most Reliable Reverse Laminar Air Flow Manufacturer and Supplier

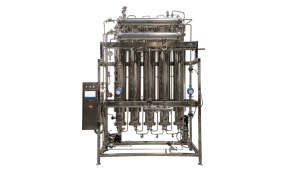

Aryan Engineers is the most reliable reverse laminar air flow manufacturer and supplier in India. We have a distinguished position among the companies producing it. Our products are well-engineered to provide a high-quality particle-free and germs free clean environment. We manufacture laminar air flow skillfully to protect your products, operators and the environment. Supreme quality and versatile utility make our products most essential in laboratories and pharmaceutical companies.

Being a reputed reverse laminar air flow supplier, our products come with certain salient features. Supreme strength, easy installation, high durability and beautiful design are prominent among them. We stick to quality in manufacturing and the supply of products, and it has given us great reach in the market. Our robust client base speaks for our popularity in the market. Contact us to own a well-crafted unit today.